Next: RCBO Safety Issues: Causes, Solutions, and Best Practices for Electrical Professionals

In today's increasingly regulated industrial landscape, electrical equipment certifications have evolved from optional quality markers to mandatory business imperatives that directly impact market access, operational safety, and bottom-line profitability.

The Role of Certifications in Industrial Electrical Equipment

BSEN61439-3BS EN61439-3 CE/UKCA Certification: Why It's Essential for Distribution Boxes

CB/SEMKO/UKCA Certification for Breakers: Ensuring Reliability and Compliance

CB/SEMKO/UKCA Certification for Fuses: Enhancing Safety and Performance

For B2B professionals operating in the electrical equipment sector, certifications represent far more than compliance checkboxes—they serve as critical business enablers that determine market accessibility, risk mitigation, and competitive positioning. In an environment where electrical failures can result in catastrophic downtime, regulatory penalties, and safety incidents, certified equipment provides the foundation for sustainable business operations.

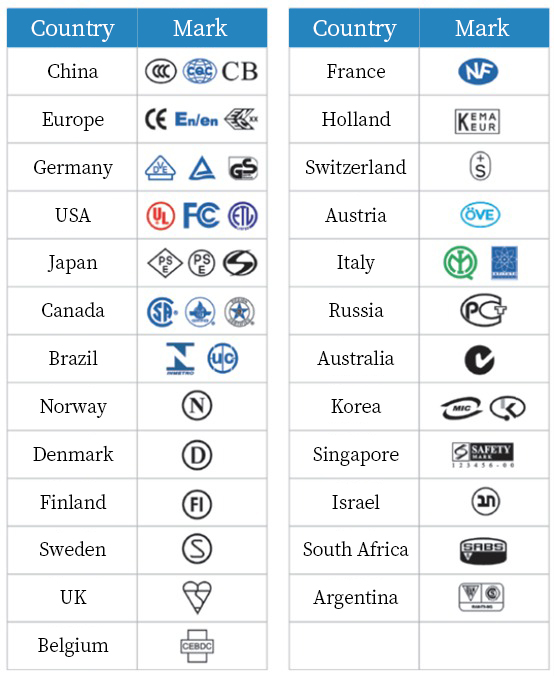

The modern industrial electrical landscape is governed by a complex framework of international and regional standards, each serving specific market requirements and safety objectives. The International Electrotechnical Commission (IEC) establishes global baseline standards that form the foundation for regional adaptations. In North America, Underwriters Laboratories (UL) standards and National Electrical Manufacturers Association (NEMA) specifications dominate, while the Occupational Safety and Health Administration (OSHA) enforces workplace safety compliance requirements.

European markets operate under the CE marking framework, requiring conformity to harmonized European standards, while the United Kingdom's post-Brexit landscape has introduced UKCA (UK Conformity Assessed) marking requirements. These certifications directly impact three critical business dimensions: regulatory compliance, risk management, and market access. Non-compliance can result in project delays, contract cancellations, insurance claim denials, and significant financial penalties.

Business Impact Reality: According to industry research, 73% of industrial electrical incidents involve non-certified or improperly certified equipment, with average downtime costs exceeding $50,000 per hour in manufacturing environments. Conversely, facilities using certified electrical components report 89% fewer safety incidents and 65% lower maintenance costs over five-year operational periods.

The certification ecosystem also influences customer trust and vendor selection processes. Engineering firms, contractors, and end-users increasingly require certification documentation during procurement processes, making it a fundamental requirement for market participation rather than a competitive differentiator. This shift has transformed certification from a quality enhancement to a market entry requirement.

Furthermore, certified equipment provides measurable ROI advantages through reduced insurance premiums, simplified regulatory compliance, enhanced operational reliability, and improved asset longevity. These factors combine to create compelling business cases for investing in certified electrical equipment, particularly for distribution boxes, breakers, and fuses that serve as critical infrastructure components in industrial and commercial facilities.

BS EN61439-3 represents the definitive European standard for switchgear and controlgear assemblies, specifically addressing distribution boards intended for installation in locations where ordinary persons have access for their operation. This standard encompasses comprehensive requirements for design verification, routine testing, and type testing procedures that ensure distribution boxes meet stringent safety, performance, and reliability criteria.

The standard addresses critical technical aspects including temperature rise limits, dielectric properties, short-circuit withstand capability, electromagnetic compatibility, and mechanical impact resistance. These requirements ensure that distribution boxes can operate safely under normal and fault conditions while maintaining accessibility for non-technical personnel in commercial and light industrial applications.

CE marking under this standard requires comprehensive technical documentation, including design calculations, test reports, risk assessments, and conformity declarations. The UKCA marking process follows similar requirements but operates under UK-specific regulations, requiring UK-based conformity assessment bodies for certain applications.

For European and UK market access, CE and UKCA certifications respectively represent non-negotiable requirements. Distribution boxes without proper certification cannot legally be placed on these markets, immediately excluding suppliers from significant revenue opportunities. The European electrical equipment market represents over €180 billion annually, while the UK market accounts for an additional £35 billion, making certification essential for accessing these substantial opportunities.

Beyond market access, certified distribution boxes provide operational advantages that translate to measurable business benefits. Certified units demonstrate verified performance under fault conditions, reducing the risk of cascading failures that can shut down entire facility sections. This reliability translates to reduced downtime costs, which average €22,000 per hour in European manufacturing facilities.

European facilities using BS EN61439-3 certified distribution boxes report 45% fewer electrical faults and 38% lower maintenance costs compared to non-certified alternatives.

Insurance implications also favor certified equipment, with many European insurers offering premium reductions of 15-25% for facilities using certified electrical infrastructure. Some insurers now require certification documentation for coverage approval, making it a prerequisite for operational insurance rather than merely a cost optimization opportunity.

For procurement professionals and engineering firms, specifying non-certified distribution boxes introduces multiple risk factors that extend beyond initial cost considerations. During compliance audits, non-certified equipment can trigger project delays, regulatory fines, and requirement for complete equipment replacement. These scenarios often result in costs that exceed 300-500% of the original equipment investment.

Project bidding processes increasingly require certification documentation as mandatory submission requirements. Suppliers unable to provide proper certification face automatic disqualification from tender processes, regardless of competitive pricing or technical capabilities. This trend has accelerated as project owners seek to transfer compliance risks to suppliers and contractors.

Long-term operational considerations also favor certified distribution boxes. Certified units typically include comprehensive technical documentation, standardized maintenance procedures, and established spare parts availability. These factors reduce lifecycle costs and simplify facility management processes, particularly important for multi-site operations requiring standardized equipment specifications.

Learn More:

What is the difference between SPN and TPN distribution board

Distribution Boards Market Competitors(2025): Laiwo VS ABB VS Siemens

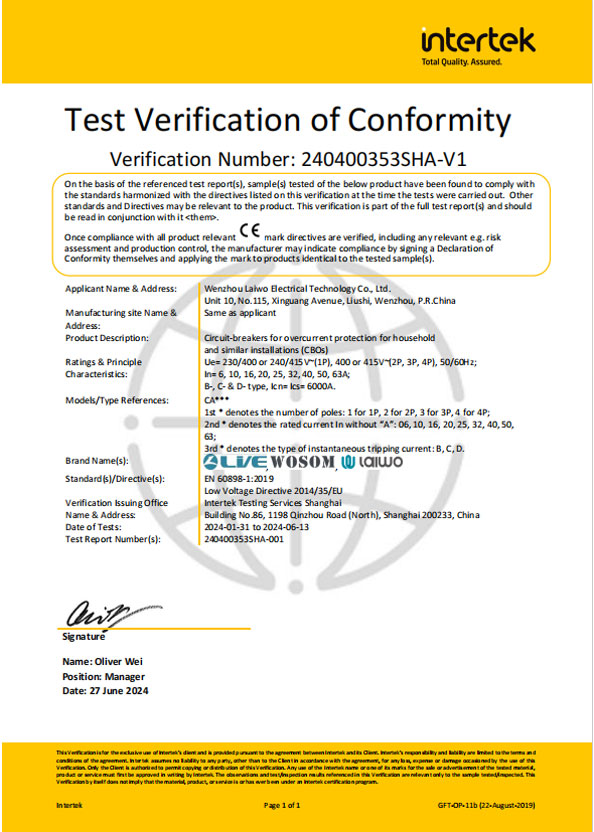

The EN61008-1 standard, along with related specifications for circuit breakers, establishes comprehensive requirements for residual current operated circuit-breakers without integral overcurrent protection for household and similar uses. CB (Certification Body) scheme certification provides international recognition through the IECEE multilateral agreement, while SEMKO certification offers Nordic market access with enhanced cold-weather performance verification.

These certifications address critical performance parameters including breaking capacity, making capacity, electrical endurance, mechanical endurance, and environmental stress resistance. Testing protocols simulate real-world operating conditions, including temperature cycling, humidity exposure, mechanical shock, and electromagnetic interference scenarios that breakers encounter in industrial applications.

UKCA certification for breakers requires compliance with UK-specific electrical safety regulations while maintaining technical equivalence to European standards. This dual-track approach ensures continued market access across European and UK markets despite regulatory divergence following Brexit.

Circuit breakers serve as the primary protection mechanism in electrical distribution systems, making their reliability critical for facility operations. Certified breakers provide verified performance characteristics that enable precise coordination calculations and predictable fault response behavior. This predictability allows engineers to design optimized protection schemes that minimize disruption during fault conditions.

In industrial applications, breaker failures can cascade through electrical systems, potentially causing widespread outages that impact entire production lines. Certified breakers demonstrate verified breaking capacity and electrical endurance characteristics that reduce failure probability by up to 78% compared to non-certified alternatives, according to international reliability databases.

Operational Excellence: Manufacturing facilities using certified breakers report average annual electrical downtime of 2.3 hours versus 8.7 hours for facilities using non-certified equipment—a 73% reduction that translates to millions in prevented production losses for large operations.

The CB scheme's international recognition provides particular value for multinational projects and standardization initiatives. Equipment certified under CB scheme protocols gains acceptance across 54 participating countries, simplifying procurement processes and enabling economies of scale for global operations.

Procurement strategies focusing solely on initial breaker costs often overlook total cost of ownership implications that emerge over operational lifecycles. Certified breakers typically include comprehensive technical specifications that enable accurate coordination studies, reducing engineering time and improving protection system effectiveness.

Non-certified breakers introduce significant risks during electrical fault conditions, where unverified performance characteristics can result in protection system miscoordination. These scenarios can escalate minor electrical faults into major system failures, potentially causing equipment damage, extended downtime, and safety hazards that far exceed the initial cost savings from purchasing non-certified equipment.

Maintenance planning also benefits from certified breaker specifications, which include established testing intervals, performance degradation indicators, and replacement criteria. This information enables predictive maintenance strategies that optimize equipment availability while managing lifecycle costs effectively.

For engineering companies and contractors, specifying certified breakers reduces professional liability exposure and simplifies compliance documentation for regulatory approvals. Many jurisdictions now require certified breakers for commercial and industrial installations, making certification a prerequisite for project approval rather than an optional quality enhancement.

Learn More:

Miniature Circuit Breaker Symbols in Electrical Diagrams

Understanding the difference between MCB RCCB and RCBO

Miniature Circuit Breaker (MCB) Market Analysis 2025: Trends, Growth Drivers & Forecast (2023-2032)

EN60269-1 establishes the fundamental requirements for low-voltage fuses, addressing construction, testing, and performance criteria that ensure reliable overcurrent protection across diverse applications. This standard encompasses critical parameters including time-current characteristics, breaking capacity, power dissipation, and mechanical integrity under normal and fault conditions.

The certification process involves comprehensive type testing that validates fuse performance across temperature ranges, current levels, and environmental conditions representative of industrial applications. Testing protocols include verification of current-time characteristics, breaking capacity demonstration, temperature rise measurement, and mechanical stress evaluation.

CB scheme certification provides international market access through standardized testing protocols recognized across participating countries. SEMKO certification adds Nordic-specific environmental testing that addresses harsh operating conditions common in northern European industrial environments. UKCA certification ensures continued UK market access while maintaining technical equivalence to European requirements.

Fuses represent the most fundamental overcurrent protection technology, providing reliable circuit interruption through predictable melting characteristics. Certified fuses offer verified time-current curves that enable precise coordination calculations and predictable protection behavior under diverse fault conditions.

The reliability advantages of certified fuses become particularly evident in critical applications where protection system failure can result in equipment damage, production interruption, or safety hazards. Certified fuses demonstrate consistent performance characteristics that reduce nuisance trips by up to 67% while providing reliable protection during genuine overcurrent conditions.

Power quality considerations also favor certified fuses, which undergo comprehensive testing to verify electromagnetic compatibility and minimize system disturbances during normal operation. These characteristics become increasingly important as facilities integrate sensitive electronic equipment that requires stable power quality for optimal performance.

Industrial facilities using certified fuses report 52% fewer protection-related equipment failures and 43% lower annual fuse replacement costs due to improved reliability and predictable performance characteristics.

Energy efficiency implications of certified fuses include verified power dissipation characteristics that contribute to overall system efficiency optimization. While individual fuse losses may appear minimal, large facilities with hundreds or thousands of fuses can achieve measurable energy savings through specification of certified, low-loss fuse technologies.

Fuse procurement decisions often focus on immediate cost considerations while overlooking long-term operational implications that significantly impact total cost of ownership. Certified fuses provide predictable performance characteristics that enable optimized maintenance scheduling and reduce unexpected replacement requirements.

Non-certified fuses introduce uncertainty in protection system coordination, potentially resulting in inappropriate trip characteristics that cause nuisance outages or inadequate protection during fault conditions. These scenarios can escalate into major system disturbances that require extensive troubleshooting and system reconfiguration to resolve.

Inventory management benefits from certified fuse standardization, which enables consolidated procurement processes and reduced spare parts inventory requirements. Certified fuses typically include comprehensive technical documentation that simplifies replacement specification and reduces the risk of incorrect fuse selection during maintenance activities.

For maintenance organizations, certified fuses offer established performance criteria that enable condition-based replacement strategies rather than time-based approaches. This optimization can reduce maintenance costs by 25-35% while improving system reliability through data-driven replacement decisions.

Regulatory compliance considerations increasingly require certified fuses for commercial and industrial applications, with many jurisdictions specifying certification requirements in electrical codes and safety regulations. This regulatory trend makes certification a compliance requirement rather than a voluntary quality enhancement.

Learn More: What is the difference between a fuse and a MCB?

Certification transcends basic compliance to become a strategic differentiator that influences customer perception, project qualification, insurance terms, and operational performance. Forward-thinking organizations leverage certification as a competitive tool that demonstrates commitment to quality, safety, and professional excellence while reducing operational risks and lifecycle costs.

The investment equation for certified distribution boxes, breakers, and fuses extends beyond initial purchase price to encompass total cost of ownership optimization across operational lifecycles. This holistic approach reveals that certification premiums typically represent 5-12% of initial equipment costs while delivering operational savings of 25-40% over five-year periods through improved reliability, reduced maintenance requirements, and enhanced operational efficiency.

The evidence clearly demonstrates that certified distribution boxes, breakers, and fuses deliver measurable business value through improved safety, enhanced reliability, regulatory compliance, and operational cost optimization. For B2B decision-makers, the question is not whether to invest in certified equipment, but how quickly to implement certification-focused strategies that deliver competitive advantage while ensuring sustainable operational excellence.

If you have any questions or require expert assistance with your electrical needs, our dedicated customer service team is ready to help. Give us a call or send us an email today and our dedicated team will provide you with the answers and support you need.

Learn More:

MCBs Guide: Types, Functions & Electrical Safety Tips

Distribution Boards: A Comprehensive Guide for Professionals and Consumers

Why IP Ratings Matter for Consumer Units?

INQUIRY NOW