In the realm of electrical systems, the distribution board stands as a cornerstone, a central nexus ensuring the safe and efficient allocation of electrical power.

Whether it's illuminating a residential abode or powering a sprawling industrial complex, the efficacy of a distribution board is paramount.

This discourse aims to demystify these critical components, offering a comprehensive exploration tailored to both discerning consumers and meticulous B2B procurement personnel.

We will delve into the intricacies of electrical distribution boards, their diverse applications, and the salient factors governing their selection and maintenance.

By the end of this article, you will have the answers of

What Components Make Up a Distribution Board?

What are the Different Types of Distribution Boards?

What is the difference between fuse box and distribution board?

RCD vs RCBO vs MCB Fuse Boxes: What’s the Difference?

2 Way to 36 Way Distribution Boards - What’s the Difference?

Functions of Distribution Boards

Application of Power Distribution Boards

How Should a Distribution Board Be Installed?

How to Choose a Distribution Board?

How to Maintain and Troubleshoot a Distribution Board?

Distribution Boards Market Analysis(2025)

laiwo Electrical - A One-Stop Solution for all your Electrical Requirements

A distribution board , commonly known as a consumer unit or fuse box, functions as the central nervous system of an electrical supply system within any given building.

According to Wikipedia, a distribution board is also known as a "panelboard, circuit breaker panel, breaker panel, electric panel, fuse box or DB box."

Its fundamental role involves receiving electrical power from the main utility source and intelligently dividing it into numerous subsidiary circuits. This distribution ensures that various areas of the property, including individual rooms, appliances, and outlets, receive the appropriate electrical energy required for their operation.

But what is the distribution board in technical terms? It's an assembly of protective devices (like circuit breakers or fuses), switching devices, and busbars, all enclosed within a robust housing. These components work in concert to safeguard electrical installations and ensure continuity of power supply.

Enclosure: The housing that protects the internal components from environmental factors and physical damage. It also serves as a safety barrier to prevent electrical contact.

Busbars: Conductive bars that serve as the main power distribution points within the board. They facilitate the flow of high currents and provide connection points for protective and switching devices.

Circuit Breakers/Fuses: These are overcurrent protective devices (OCPDs) that interrupt the flow of current in the event of an overload or short circuit. Miniature circuit breakers are resettable, while fuses are single-use and must be replaced after operation.

Residual Current Circuit Breaker (RCCB): RCCBs are crucial safety devices, often required by electrical codes in several regions. These sensitive breakers are typically installed alongside MCBs. They are designed to detect even the smallest imbalance between phase conductors, ensuring enhanced protection.

Residual Current Breakers with Overcurrent Protection (RCBOs): RCBO are advanced devices that combine the functions of both an RCD and a Miniature Circuit Breaker (MCB) into a single, compact unit. They offer comprehensive protection against both overcurrents (including overload and short circuit) and earth leakage currents.

Main Switch Disconnector(Isolators): The main switch, often referred to as the "Isolators" serves as the primary control switch for the entire electrical supply to the building. It enables complete isolation of all power in an emergency or during maintenance, acting as a crucial safety cut-off. While it provides isolation, it typically does not offer electrical protection itself.

Surge Protective Devices (SPDs): SPD are designed to safeguard electrical systems and sensitive electronic equipment against transient overvoltages caused by external factors like lightning strikes or internal switching operations within the electrical grid.

Learn More:

MCB Symbols in Electrical Diagrams

Understanding the difference between MCB RCCB and RCBO

Circuit Breakers Guide: Types, Functions & Electrical Safety Tips

The diversity of electrical needs necessitates a corresponding variety in distribution boards. Here's a breakdown of some common types:

LAIWO’s Metal Distribution Board / Consumer unit series is engineered as the backbone of modern electrical distribution systems, combining robust construction, advanced protection capabilities, and versatile configurations. Designed for commercial, industrial, and residential applications, these units deliver reliable power control, surge protection, and seamless integration with diverse electrical setups. Built to meet global safety standards, they ensure optimal performance in demanding environments.

-1318.jpg)

LAIWO’s Metal Garage/EV Consumer Units are engineered as the backbone of modern electrical systems, combining robust, fully enclosed metal construction, advanced IP40/IP65 protection, and versatile configurations for seamless integration. Designed for commercial, industrial, residential, and EV charging applications, these units deliver corrosion-resistant durability—enhanced by automated polyester powder coating—and flexible connectivity via neutral cable/live busbar setups. Built to meet CE/UKCA standards (BSEN61439-3), they ensure reliable performance in indoor and outdoor environments.

Learn More:

EV Charger Consumer Unit Guide

.jpg)

LAIWO's TP&N Metal Distribution Boards are the robust and reliable backbone your commercial and industrial electrical systems demand. Designed for the most demanding environments, our TP&N boards are finished in a sleek RAL7035 white, offering a contemporary aesthetic that complements any professional setting. They operate flawlessly on AC380V/415V 50/60Hz systems and are built to handle significant loads, with options for maximum loading currents up to 125A (100A) or 250A.

Learn More:

Your Definitive Guide to TP&N Distribution Boards

What is the difference between SPN and TPN distribution board

.jpg)

LAIWO's Plastic Modular Distribution Board/ DB Box the ideal solution for protecting your critical electrical components within commercial, industrial, and residential settings across the UK and Europe. Designed for flexibility and safety, these enclosures offer a reliable housing for a wide range of modular devices, ensuring seamless integration and long-lasting performance.

.jpg)

LAIWO's Plug-in MCB Metal Distribution Boards offer a robust and streamlined solution for power distribution in commercial and industrial environments across the UK and Europe. Combining classic style with advanced functionality, these distribution boxes are engineered for quick, secure, and efficient installation of plug-in miniature circuit breakers (MCBs).

Featuring a classic design with a textured RAL7035 white paint finish, these units are built to seamlessly integrate into various professional settings. They are designed for reliable operation on AC240V/415V 50/60Hz systems and can handle a maximum loading current of up to 100A, making them suitable for a wide range of applications.

|

Characteristic |

Traditional Fuse Box |

Modern Electrical Distribution Board (Consumer Unit/Panelboard) |

|

Primary Protective Device |

Fuses (Rewireable, Cartridge) |

Circuit Breakers (MCBs), RCDs, RCBOs |

|

Protection Type |

Basic Overload, Short Circuit (via fuse melting) |

Comprehensive: Overload, Short Circuit, Electric Shock (Earth Leakage), Surge, Arc Fault (recommended) |

|

Reset Mechanism |

Requires physical replacement of blown fuse |

Easy reset by flipping a switch |

|

Response to Fault |

Fuse melts, breaking circuit (one-time use) |

Circuit breaker "trips" (thermal/magnetic), RCD/RCBO detects imbalance (reusable) |

|

Shock Protection |

Limited/None (basic overcurrent protection only) |

Integrated and highly sensitive (RCDs/RCBOs) |

|

Fire Protection |

Limited; plastic/wooden enclosure can be a fuel source; no arc fault detection |

Enhanced: Non-combustible (metal) enclosure, RCDs for insulation faults, AFDDs recommended for arc faults |

|

Surge Protection |

None |

Integrated (SPDs) or easily added |

|

Enclosure Material |

Often plastic, bakelite, or wood |

Typically metal (non-combustible) |

|

Capacity for Modern Loads |

Low; not designed for high electrical demands of modern homes |

High; designed to accommodate increased electrical loads and numerous circuits |

|

Maintenance |

Higher effort; requires spare fuses and replacement knowledge |

Lower effort; easy resetting, clear fault indication |

|

Regulatory Compliance |

Generally non-compliant with modern electrical codes and safety standards; cannot be fitted in new installations |

Fully compliant with current electrical regulations (e.g., BS 7671:2018); often legally mandated |

|

Typical Application |

Older homes (pre-1960s, some up to 1980s) |

Modern residential, commercial, and industrial installations |

The difference between a fuse box and a consumer unit lies mainly in their technology, safety features, and ease of use, although they serve the same fundamental purpose of distributing electricity in a home and protecting circuits from overloads.

A fuse box represents an older generation of electrical control units, historically known as a fuse board or, colloquially, a "consumer unit" in its early contexts, serving as a central point for both electricity distribution and circuit protection.

In modern electrical systems, what was traditionally called a fuse box has evolved significantly and is now known by several different terms depending on the region and context. In domestic settings, particularly in the UK, it's typically called a consumer unit, while in broader electrical terminology, it's referred to as a distribution board. In North American contexts, a fuse box is now commonly called an electrical panel, breaker box, or circuit breaker panel.

Learn More:

What is a fuse box?

What is the difference between fuse box and distribution board?

| Device Type | How it works | What it protects against | Why use it | Summary |

|---|---|---|---|---|

| RCD fuse box | Monitors current balance between live and neutral. Trips if imbalance (residual current) detected. | Electric shocks (detects leakage currents as low as 30mA). Reduces fire risk from faulty wiring or insulation. Does NOT protect against overloads or short circuits. | Required by modern UK regulations for most domestic circuits. Provides centralized protection for multiple circuits. Preferable to individual socket RCDs. | Fuse box (consumer unit) with RCDs to detect leakage currents, quickly disconnecting power to prevent shocks and reduce fire risk. Works alongside MCBs or RCBOs for full protection. |

| RCBO fuse box | Each circuit is protected by its own RCBO. If leakage current or overcurrent fault occurs, only the faulty circuit is isolated without affecting others. Includes a main switch to isolate the entire installation. | Electric shocks (detects leakage currents). Overloads and short circuits per circuit. | Provides individual circuit protection (faults don’t interrupt other circuits). Space-saving as it combines RCD and MCB functions. Meets modern wiring regulations (e.g. UK 18th Edition BS7671). | A modern consumer unit that protects each circuit against electric shocks, overloads, and short circuits. Preferred for safe, efficient installations requiring selective circuit isolation and full compliance. |

| MCB fuse box | Uses bimetallic strip for overload (heats and bends to trip). Uses electromagnetic coil for short circuits (trips instantly). Resettable after fault clearance. | Overloads and short circuits. Prevents damage to wiring and appliances. | Safer and more convenient than fuses (quick reset, no replacement). Common in residential, commercial, industrial circuits. Helps isolate faults to specific circuits. | Fuse box with MCBs providing reliable, resettable protection against overloads and short circuits, enhancing safety and convenience in installations. |

Learn More:

RCD vs RCBO vs MCB Fuse Boxes: What’s the Difference?

Simply put, a "way" refers to a single module position within the board designed to house one protective device (circuit breaker or fuse position). Each way typically protects one final circuit. Therefore:

A 2 way distribution board has space for just two protective devices, controlling two circuits.

A 6 way distribution board accommodates six devices and six circuits.

A 12 way distribution board manages twelve.

A 24 way distribution board handles twenty-four.

A 36 way distribution board is a significant unit handling thirty-six circuits.

The number of ways directly correlates with the board's capacity to manage electrical loads.

More ways allow for greater subdivision of the electrical system, enabling dedicated circuits for specific areas or high-demand appliances, enhancing safety through targeted protection, and simplifying fault-finding and maintenance.

It's about granular control and safety segregation. The physical size of the board also scales with the way count.

Learn More: 2 Way to 36 Way Distribution Boards - What’s the Difference?

Power Distribution

Divides electrical power from the main supply into multiple circuits to safely and efficiently power lighting, outlets, HVAC, and equipment without overloading any circuit.

Circuit Protection

Contains circuit breakers, fuses, and RCDs that cut off power during overcurrent, short circuits, or faults to prevent fires, equipment damage, and injuries.

Load Management

Distributes power strategically across circuits to manage heavy loads and avoid overloading, ensuring stable and safe operation of appliances and machinery.

Control and Isolation

Allows individual circuits to be isolated for maintenance or emergencies, enabling safe and convenient electrical management.

Centralized Organization

Provides a central hub for all circuit connections and protective devices, simplifying maintenance, troubleshooting, and system organization.

Expansion Flexibility

Supports easy addition of new circuits without major rewiring, meeting growing power needs in homes, commercial buildings, or industrial facilities.

Safety Compliance

Designed to meet safety standards and regulations, often including grounding to protect people and property from electrical hazards.

| Sector / Application | Description and Uses |

|---|---|

| Residential Buildings | Distributing power to various household circuits such as lighting, appliances, and HVAC; enabling easy circuit isolation and overload protection for home safety and convenience. |

| Commercial Buildings | Power distribution for offices, retail stores, restaurants, malls, and other commercial spaces, supporting lighting, HVAC, elevators, office equipment, and ensuring business continuity without downtime. |

| Industrial Facilities | Managing heavy electrical loads for manufacturing plants, factories, warehouses, and processing units; powering heavy machinery, conveyor belts, motor control, and maintaining stable production processes. |

| Healthcare and Hospitals | Ensuring reliable, uninterrupted power for critical medical devices such as ventilators, imaging equipment, and emergency systems, preventing failures in life-critical situations. |

| Construction Sites | Temporary and flexible power distribution to construction tools and equipment; enabling safety and efficient control in dynamic work environments. |

| Infrastructure (Airports, Data Centers, Utilities) | Managing continuous power supply for critical infrastructure where downtime is costly; advanced boards with real-time monitoring keep systems active during outages or faults. |

| Renewable Energy Integration | Handling variable power flows and protecting grids integrated with solar, wind, and other renewables; enabling microgrids and smart energy management. |

| Smart Energy Management | Modern smart distribution boards with IoT integration provide remote monitoring, load management, demand response capabilities, predictive maintenance, and energy optimization in all sectors. |

Proper installation is crucial to ensure the safe and reliable operation of a distribution board. Here are some essential guidelines:

Qualified Personnel: Installation should only be carried out by qualified electricians who are familiar with relevant codes and regulations.

Location: The board should be installed in an accessible, well-ventilated location, away from moisture, dust, and other contaminants.

Mounting: The board must be securely mounted to a stable surface to prevent vibration or movement.

Wiring: Wiring must be carried out in accordance with the manufacturer's instructions and relevant wiring regulations. Proper conductor sizing, termination, and labeling are essential.

Testing and Commissioning: After installation, the board must be thoroughly tested and commissioned to ensure proper operation and safety.

Learn More: How to Wire a Garage Consumer Unit: A Comprehensive Guide

For B2B procurement personnel tasked with sourcing distribution boards, a meticulous approach is paramount. Several factors must be considered to ensure the selected board meets the specific requirements of the application:

Current Rating: The board's current rating must be sufficient to handle the maximum anticipated load. Overestimation can lead to unnecessary expense, while underestimation poses a significant safety hazard.

Voltage Rating: The voltage rating of the board must be compatible with the supply voltage.

Number of Circuits: The board must have an adequate number of circuits to accommodate all the connected loads, with room for future expansion.

Enclosure Type: The enclosure must be appropriate for the environment in which the board will be installed. Factors such as ingress protection (IP) rating, corrosion resistance, and mechanical strength must be considered.

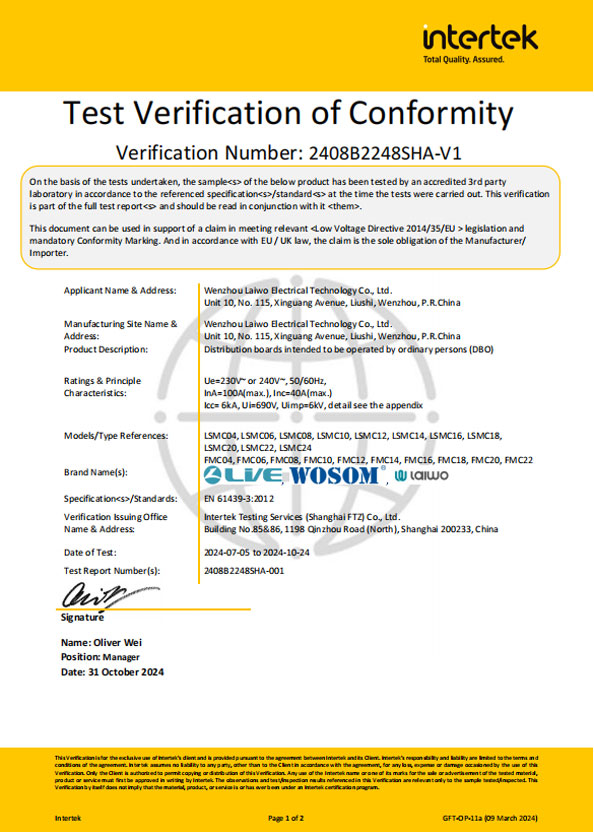

Standards and Compliance: The board must comply with relevant industry standards and safety regulations.

Manufacturer Reputation: Opting for a reputable manufacturer, such as laiwo distribution board, ensures quality, reliability, and after-sales support.

Modularity and Expandability: A modular design allows for easy expansion or modification of the board as needs evolve.

Short-Circuit Withstand Capacity: The board must be able to withstand the thermal and mechanical stresses of a short-circuit fault.

Regular maintenance is essential to prolong the lifespan of a distribution board and prevent potential problems. Key maintenance activities include:

Visual Inspection: Periodically inspect the board for signs of damage, corrosion, or loose connections.

Cleaning: Clean the board regularly to remove dust and debris that can impede ventilation and contribute to overheating.

Torque Testing: Check and re-torque connections to ensure they are tight and secure. Loose connections can lead to overheating and electrical faults.

Insulation Testing: Regularly test the insulation resistance of the board's wiring to identify potential insulation breakdown.

Circuit Breaker Testing: Test the operation of circuit breakers to ensure they trip correctly under fault conditions.

Troubleshooting electric distribution board issues requires a systematic approach. Common problems include:

Tripped Miniature Circuit Breakers: Identify and address the cause of the trip before resetting the MCB. Common causes include overloads, short circuits, and ground faults.

.png)

Overheating: Overheating can be caused by loose connections, overloads, or inadequate ventilation.

Voltage Fluctuations: Voltage fluctuations can be caused by problems with the supply, the board's wiring, or connected loads.

Complete Power Loss: A complete power loss can be caused by a tripped main breaker, a fault in the supply, or a problem with the board itself.

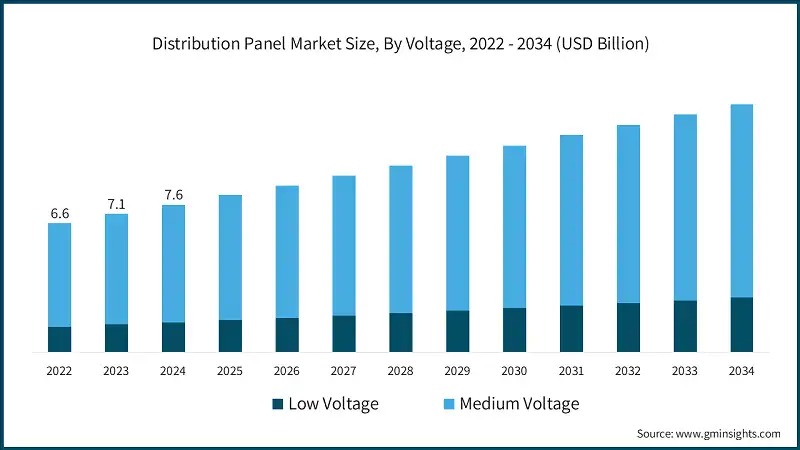

The global distribution boards market has demonstrated a consistent upward trajectory over the past three years. According to data from GMI, the global distribution panel market was valued at USD 6.6 billion in 2022, increasing to USD 7.1 billion in 2023, and reaching USD 7.6 billion in 2024. These figures indicate a steady and robust growth rate within this period.

Learn More: Distribution Boards Market Analysis(2025): B2B Trends, Opportunities and Procurement/Distribution Strategies

Laiwo Electrica (China): A Chinese manufacturer specializing in electrical distribution and protection equipment, Laiwo focuses on providing comprehensive low-voltage distribution solutions for residential, commercial, and industrial applications through their diverse product portfolio.

ABB (Switzerland): A leading player in power and automation technologies, ABB's Electrification business segment provides comprehensive distribution automation solutions, accounting for a significant portion of its total revenue.

Learn More: Distribution Boards Market Competitors(2025): Laiwo VS ABB VS Siemens

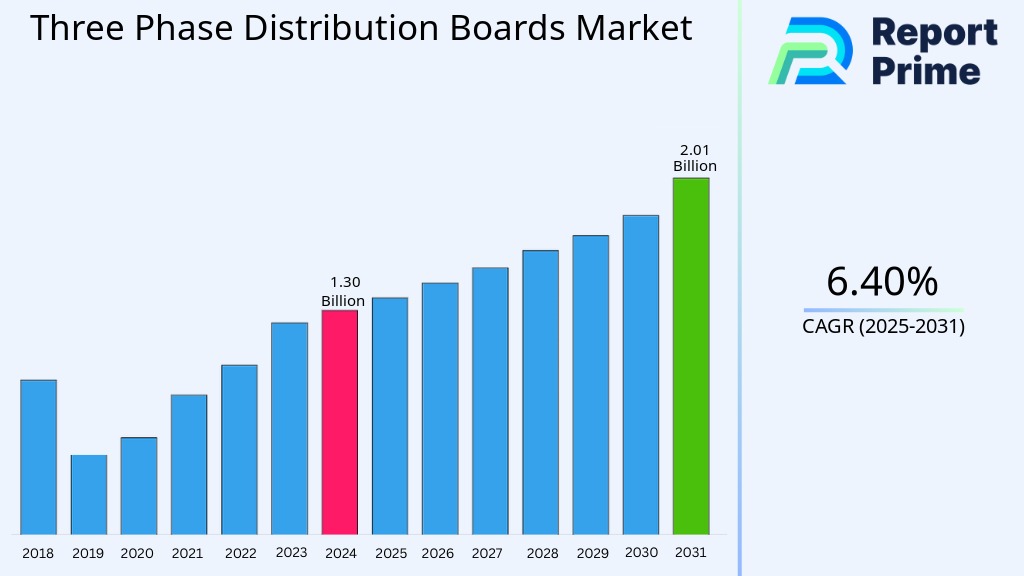

The global 3-Phase Distribution Boards market is a cornerstone of modern electrical infrastructure, vital for efficient and safe power distribution in high-demand environments. Valued at approximately $1.3 billion in 2024, this market is poised for significant growth, projected to reach $2.01 billion by 2031, demonstrating a Compound Annual Growth Rate (CAGR) of around 6.4% from 2025 to 2031. This expansion is primarily fueled by escalating global electricity demand, rapid urbanization, industrialization, and substantial investments in grid modernization and renewable energy integration

Learn More: 3 Phase Distribution Boards Market Analysis: Trends, Opportunities, and Strategic Insights

LAIWO specializes in high-performance distribution boxes and distribution boards, including metal distribution boxes , garage / EV consumer unit, TP&N/MCB metal distribution board, and plastic distribution boxes. It also provides circuit breakers (MCB, RCCB, RCBO), surge protectors, and other circuit protection devices.

As an ISO-certified factory with more than 20 years of ODM/OEM expertise, we provide comprehensive distribution systems to help customers meet power needs in multiple scenarios.

If you have any questions or require expert assistance with your electrical needs, our dedicated customer service team is ready to help. Give us a call or send us an email today and our dedicated team will provide you with the answers and support you need.

ANS:

Raw Materials: UL/CE certified, conductivity/protection controlled.

Processing: Standardized precision manufacturing, full-process QC.

Inspection: 100% tested (voltage/insulation/temp rise), traceability reports.

ANS:  Click here for Laiwo product certificates

Click here for Laiwo product certificates

How does Laiwo Electrical's manufacturing technology and materials contribute to thereliability of their RCCBs and RCBOs?

Laiwo Electrical's RCCBs (Residual Current Circuit Breakers) and RCBOs (Residual Current Circuit Breakers with Overcurrent Protection) are designed for reliability through the use of advanced manufacturing technologies and high-quality materials. These devices use sensitive toroids and electronic circuits to detect even minute imbalances in electrical currents, triggering a rapid disconnection of the power supply to prevent electric shocks and fire hazards.

INQUIRY NOW