Next: 3 Phase Distribution Boards Market Analysis: Trends, Opportunities, and Strategic Insights

Decoding the "Way": Modules, Circuits, and Capacity

2-Way to 6-Way Distribution Boards

8-Way to 18-Way Distribution Boards

20 Way to 36 Way+ Distribution Boards

Phase Matters: Single-Phase vs. Three-Phase Distribution Boards

Beyond the Way Count: TPN, SPN, SPDs, and Other Features

Choosing the Right Distribution Board

Distribution Board Installation

Laiwo Electrical: OEM/ODM Specialist for Compliant Consumer Units & Distribution Boards

Distribution boards (DB), also known as consumer units, fuse boxes or breaker panel, are essential components in electrical installations that distribute electrical power from a main supply to various circuits throughout a building.

Its primary roles are distribution, protection (using devices like MCBs, RCDs, RCBOs, and fuses), isolation, and metering (in some configurations).

Selecting the correct way, type and size isn't just about convenience; it's fundamental to electrical safety, system efficiency, and compliance with wiring regulations.

A distribution board is an electrical panel that divides an electrical power feed into subsidiary circuits while providing protective fuses or circuit breakers for each circuit. It serves as the central hub for electrical distribution within a building, ensuring safe and efficient power supply to different areas and appliances.

The primary functions of a distribution board include:

Distributing electrical power from the main supply to individual circuits

Providing overcurrent protection through circuit breakers or fuses

Enabling isolation of individual circuits for maintenance or emergency purposes

Incorporating residual current devices (RCDs) for electrical safety

Facilitating electrical system monitoring and control

Learn More: Distribution Boards: A Comprehensive Guide for Professionals and Consumers

Simply put, a "way" refers to a single module position within the board designed to house one protective device (circuit breaker or fuse position). Each way typically protects one final circuit. Therefore:

A 2 way distribution board has space for just two protective devices, controlling two circuits.

A 6 way distribution board accommodates six devices and six circuits.

A 12 way distribution board manages twelve.

A 24 way distribution board handles twenty-four.

A 36 way distribution board is a significant unit handling thirty-six circuits.

The number of ways directly correlates with the board's capacity to manage electrical loads.

More ways allow for greater subdivision of the electrical system, enabling dedicated circuits for specific areas or high-demand appliances, enhancing safety through targeted protection, and simplifying fault-finding and maintenance.

It's about granular control and safety segregation. The physical size of the board also scales with the way count.

These smaller units are the workhorses of simple, low-demand applications. Characterised by their compact footprint, they prioritise space efficiency where extensive circuitry isn't required.

2-Way Distribution Boards: The most basic configuration. Often found protecting a single, dedicated high-power circuit (like an immersion heater or cooker) alongside one general lighting circuit in a very small outbuilding, garage, or as a sub-main feeding another board.

View Laiwo 2 Way IP20 Plastic Distribution Boxes

4 Way Distribution Board: A step up, commonly seen in small sheds, garage, garden offices, or as a sub-board for an annexe.

View Laiwo 4 Way IP65 AL Garage Unit Surface Mounted

5 Way Distribution Board: Offers slightly more flexibility than a 4-way, allowing for an extra dedicated circuit or spare way in a small setup.

View Laiwo 5 Way IP65 AL EV Charging Consumer Unit Surface Mounted

6 Way Distribution Board: Represents the practical minimum for many small homes, flats, or extensions.

This category represents the sweet spot for most standard residential properties, small businesses, and commercial units. They offer a significant step up in capacity and flexibility.

8 Way Distribution Board: A solid choice for larger flats, small houses, or significant extensions. Allows for proper circuit separation: multiple lighting circuits, several ring finals for different rooms/zones, dedicated circuits for major appliances (cooker, hob, oven, shower, immersion heater), and often a spare way or two.

The 8 way tpn distribution board is frequently used in small shops, offices, or light industrial units to distribute three-phase power to multiple machines or areas.

10 Way & 12 Way Distribution Boards: These are arguably the most common and recommended sizes for modern 3-4 bedroom family homes.

12 way distribution board comfortably accommodates:

Multiple lighting circuits (e.g., ground floor, first floor, outside).

Multiple ring final circuits (e.g., kitchen, living room, bedrooms, upstairs sockets).

Dedicated circuits for cooker, electric shower, immersion heater, boiler, oven/hob, garage/shed supply.

Essential safety devices like RCDs or RCBOs.

1-2 spare ways for future additions (e.g., EV charger, hot tub).

The 12 way 3 phase distribution board is a standard choice for distributing power in larger flats, small offices, or retail units requiring three-phase for HVAC or specific equipment.

6 Way & 18 Way Distribution Boards: Ideal for larger homes with high electrical demands (multiple bathrooms with electric showers, extensive kitchen appliances, home offices, outbuildings), or small commercial premises like cafes, salons, or workshops.

The 16 way distribution board and 18 way distribution board provide ample space for comprehensive circuit separation, enhanced safety via dual RCD configurations or full RCBO protection, and generous spare ways.

16 way 3 phase distribution board and 18 way 3 phase distribution board units handle more complex three-phase distribution needs in these settings.

When electrical demands soar, high-density distribution boards step in. These are the domain of larger commercial buildings, industrial facilities, data centres, and complex residential installations like large multi-occupancy buildings or mansions.

20 Way & 22 Way Distribution Boards: Serve as robust sub-main boards in large buildings or main boards for substantial commercial units, larger workshops, or medical/dental practices requiring numerous dedicated circuits for equipment, HVAC, and extensive lighting/socket networks.

The 20 way 3 phase distribution board is a common starting point in this tier.

24 Way Distribution Board: A very common industrial and commercial standard size. Used extensively as floor distribution panels in office blocks, main boards in medium-sized factories, retail units, restaurants, and server rooms. Provides significant capacity for complex circuiting and separation of critical loads.

28 Way, 30 Way, 32 Way Distribution Boards: Cater to even larger-scale requirements. Found in industrial plants, large commercial complexes, data halls, and buildings with complex mechanical and electrical systems requiring extensive circuit control and separation. 30 way distribution board and 32 way distribution board units manage substantial loads. 30 way 3 phase distribution board configurations are typical.

36 Way Distribution Board & Beyond (40, 42, 48, 54, 60, 72 Way): Represent the upper echelon of standard distribution board sizes. These are employed in heavy industry, large data centres, major commercial developments, hospitals, and large infrastructure projects. They manage vast numbers of circuits, often incorporating complex busbar systems, advanced monitoring, and high fault-level protection.

The 36 way distribution board and 36 way 3 phase distribution board are significant units, while even larger ways like 54 way distribution board or 72 way distribution board handle extreme densities. 36 way tpn distribution board specifications are crucial for these applications.

Learn More:

View Laiwo 4 Way to 22 Way Metal Distribution Boards(DB Box)

View Laiwo 4 Way to 24 Way Metal TP&N Distribution Board

View Laiwo 4 Way to 36 Way Plastic Distribution Boxes

View Laiwo 4 Way to 16 Way Single Phase Plug-in MCB Metal Distribution Board (DB Box)

View Laiwo 12 Way to 36 Way Three Phase Plug-in MCB Metal Distribution Board (DB Box)

The electrical supply phase is a critical differentiator fundamentally impacting the board's design and application:

Single-Phase Distribution Board: Receives a single-phase 230V AC supply (Line & Neutral). All circuits within a single phase distribution board operate at 230V. Protective devices (MCBs, RCBOs) are typically single-pole (SP) or single-pole + neutral (SPN).

Three-Phase Distribution Board (3 Phase Distribution Board): Receives a three-phase 400V AC supply (L1, L2, L3 & Neutral). Used in commercial, industrial, and some larger domestic properties (e.g., with large workshops, heat pumps, or EV chargers).

Learn More:

Your Definitive Guide to TP&N Distribution Boards

What is the difference between SPN and TPN distribution board

While the number of ways and phase are paramount, several other features define a distribution board's suitability:

Enclosure Material & Rating: Metal (common industrial) or insulated plastic (common domestic/commercial). Ingress Protection (IP) ratings (e.g., IP65) are vital for boards in damp, dusty, or outdoor environments (garages, workshops, plant rooms).

View Laiwo IP65 WHT Plastic Distribution Box Surface Mounted(ABS/Outdoor)

Main Switch Type & Rating: The main isolator must match the incoming supply capacity

View Laiwo Surface Mounted 100A/125A Main Switch Consumer Unit

Surge Protection Devices (SPDs): SPDs protect sensitive electronic equipment from voltage surges caused by lightning or grid switching.

View Laiwo Surface Mounted SPD Populated Consumer Unit

Assess Electrical Load: Calculate the total connected load (kW or kVA) and diversity (how much load operates simultaneously). This determines the required main switch rating and overall capacity.

Count Essential Circuits: List every required circuit (lighting, sockets per area, dedicated appliances - cooker, shower, EV charger, boiler, HVAC, machinery, sockets for IT). Don't forget circuits for outbuildings or garages.

Determine Phase Requirement: Is the incoming supply single-phase or three-phase? What loads require three-phase power? Choose the board phase accordingly.

Calculate Minimum Ways: Crucially, add spare ways (10-20% minimum is recommended for future expansion). This gives your minimum way count. Searches like spare ways in distribution board and distribution board spare ways underscore this need.

Select Protection Strategy: Prioritise safety and convenience. RCBOs on every circuit offer the highest level of protection and circuit independence, avoiding the "all lights off" scenario of an RCD trip affecting multiple circuits. Budget may influence this choice, but RCBOs are increasingly standard.

Consider Special Features: Is an SPD required? Is the environment demanding a specific IP rating? Is TPN switching needed for any large three-phase equipment? Do you need metering? Dimensions and mounting type are practical constraints.

Consult Regulations & Professionals: Engage a qualified electrician for the assessment, specification, and installation.

2-Way to 8-Way Distribution Board: Simple installation procedures with basic tools and minimal structural modifications. Suitable for DIY enthusiasts with appropriate electrical knowledge, though professional installation is recommended.

12-Way to 18-Way Distribution Board: Moderate complexity requiring professional installation. May necessitate structural modifications and coordination with other building services.

24-Way to 36-Way Distribution Board: Complex installations requiring qualified electricians and potentially structural engineering input. Coordination with building management systems and other electrical infrastructure is essential.

Understanding the differences between distribution boards with different numbers of ways boils down to understanding the complexity and scale of the electrical load it needs to manage. The number of ways dictates circuit capacity, while the phase (single or three phase) determines the type of loads it can handle and the power available. Features like TPN, SPDs, IP rating, and protection strategy (RCDs vs RCBOs) add critical layers of functionality and safety.

If you have any questions or require expert assistance with your electrical needs, our dedicated customer service team is ready to help. Give us a call or send us an email today and our dedicated team will provide you with the answers and support you need.

ANS:

Raw Materials: UL/CE certified, conductivity/protection controlled.

Processing: Standardized precision manufacturing, full-process QC.

Inspection: 100% tested (voltage/insulation/temp rise), traceability reports.

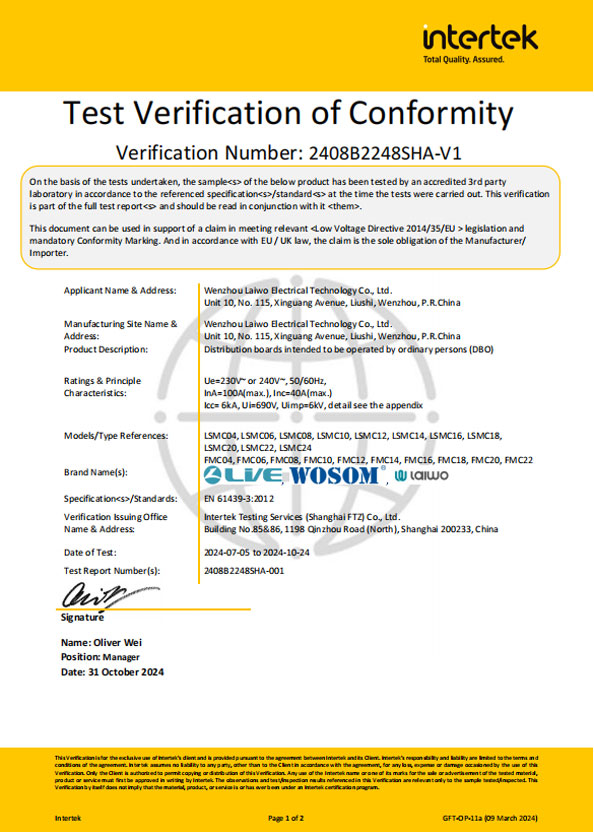

ANS:  Click here for Laiwo product certificates

Click here for Laiwo product certificates

How does Laiwo Electrical's manufacturing technology and materials contribute to thereliability of their RCCBs and RCBOs?

Laiwo Electrical's RCCBs (Residual Current Circuit Breakers) and RCBOs (Residual Current Circuit Breakers with Overcurrent Protection) are designed for reliability through the use of advanced manufacturing technologies and high-quality materials. These devices use sensitive toroids and electronic circuits to detect even minute imbalances in electrical currents, triggering a rapid disconnection of the power supply to prevent electric shocks and fire hazards.

INQUIRY NOW