This comprehensive guide examines the critical selection criteria between ABS, polycarbonate (PC), and Nylon materials for circuit breaker enclosures across residential, commercial, and industrial applications. The analysis compares these engineering thermoplastics across key performance indicators including mechanical strength, impact resistance, flame retardancy, UV stability, and environmental resilience.

For outdoor consumer unit enclosure applications, polycarbonate emerges as the superior choice due to its exceptional weather resistance and impact strength. ABS enclosures provide the most cost-effective solution for standard indoor applications where extreme conditions aren't anticipated, while Nylon offers unparalleled performance in high-temperature industrial environments and chemically aggressive settings.

The guide further explores essential certification requirements (UL, CE/UKCA, BS EN 61439-3), installation best practices, and lifecycle cost considerations to inform procurement decisions. With proper material selection and installation, electrical professionals can optimize safety, compliance, and long-term value for MCB electrical enclosure, distribution box enclosure, and consumer unit enclosure applications across diverse operating environments.

Material Comparison: ABS vs PC vs Nylon

Application-Specific Performance Considerations

Certification and Compliance Requirements for Plastic Enclosures

| Property | ABS | Polycarbonate (PC) | Nylon |

|---|---|---|---|

| Tensile Strength (MPa) | 30-45 | 55-75 | 70-100 |

| Impact Resistance | Good | Excellent | Good to Very Good |

| Heat Deflection Temperature (°C) | 80-100 | 125-140 | 180-200+ |

| UV Resistance | Poor (without stabilization) | Excellent | Fair to Good |

| Moisture Absorption | Moderate | Low | High |

| Flammability Rating | UL 94 HB | UL 94 V-0/V-2 | UL 94 V-2/V-0 |

| Chemical Resistance | Good to oils, acids | Good to acids, oils | Excellent to oils, chemicals |

| Cost Ratio | 1.0 | 1.3-1.5 | 1.5-2.0 |

When selecting materials for circuit breaker enclosures, understanding the distinct properties of each material is essential for making informed decisions that balance performance, cost, and application requirements.

ABS plastic offers a unique combination of strength, affordability, and processability, making it one of the most common choices for MCB enclosure plastic and RCD enclosure plastic applications.

Strength and Impact Resistance: ABS provides good impact resistance, particularly at lower temperatures, with a tensile strength ranging between 30-45 MPa. This makes it suitable for applications where moderate physical protection is required

Fire Performance: Standard ABS typically carries a UL 94 HB flammability rating, though flame-retardant versions are available for electrical applications where enhanced fire resistance is required

Environmental Resistance: ABS offers decent chemical resistance to many common substances but is susceptible to UV degradation when used outdoors without stabilizers. It also has moderate resistance to moisture absorption compared to other materials

Cost Considerations: ABS is generally the most cost-effective option among engineering thermoplastics, with both material and processing costs being relatively low

Polycarbonate stands out for its exceptional impact strength and clarity, making it ideal for applications where visibility or superior protection is required.

Strength and Impact Resistance: PC offers exceptional impact resistance—up to 10 times greater than ABS in some formulations—and tensile strength typically ranging from 55-75 MPa. This makes it suitable for applications where vandal resistance or protection against severe impacts is concerned .

Fire Performance: Polycarbonate typically achieves UL 94 V-0 or V-2 ratings, indicating good flame retardancy properties that make it suitable for electrical applications where fire safety is a priority .

Environmental Resistance: PC exhibits excellent resistance to UV radiation (when properly stabilized), temperature fluctuations (-40°C to 120°C continuous use), and moisture absorption. These properties make it well-suited for outdoor consumer unit enclosure applications .

Cost Considerations: Polycarbonate commands a higher price point than ABS, typically 30-50% more expensive depending on formulation and quantity. However, its durability often justifies the premium in demanding applications .

Nylon offers exceptional mechanical properties and heat resistance, making it suitable for the most demanding electrical applications.

Strength and Impact Resistance: Nylon boasts the highest tensile strength among the three materials (70-100 MPa) and excellent wear resistance, though its impact resistance can be lower than PC in some formulations. This combination makes it ideal for components subject to mechanical stress .

Fire Performance: Nylon typically achieves UL 94 V-2 ratings, with some glass-reinforced formulations reaching V-0. It also has a higher heat deflection temperature than either ABS or PC, maintaining structural integrity at elevated temperatures .

Environmental Resistance: Nylon offers excellent resistance to oils, chemicals, and abrasion, but has a tendency to absorb moisture from the environment (hygroscopicity), which can affect dimensional stability and electrical properties in humid conditions .

Cost Considerations: Nylon is generally the most expensive option among the three materials, with costs 50-100% higher than ABS. Processing costs are also typically higher due to the need for pre-drying and higher processing temperatures.

Learn More:

Why IP Ratings Matter for Consumer Units?

2 Way to 36 Way Distribution Boards - What’s the Difference?

Metal Vs. Plastic Distribution Boxes: Choosing The Right One For Your Project

| Application | Recommended Material | Key Considerations |

|---|---|---|

| Outdoor Consumer Units | Polycarbonate | UV stability, temperature resistance, impact resistance |

| Residential MCB Enclosures | ABS | Cost-effectiveness, adequate protection for indoor use |

| Industrial Breaker Enclosures | Nylon or Polycarbonate | Chemical resistance, heat resistance, durability |

| Transparent Enclosures | Polycarbonate | Natural clarity, impact resistance |

| High-Temperature Environments | Nylon | Heat deflection temperature, mechanical strength |

| Cost-Sensitive Projects | ABS | Lowest material cost, ease of processing |

The optimal material selection for circuit breaker enclosures varies significantly based on the specific application and operating environment.

For outdoor consumer unit enclosure applications, environmental resistance becomes a critical factor. Polycarbonate excels in these applications due to its exceptional UV resistance and ability to maintain properties across a wide temperature range. The combination of UV stability and impact resistance makes PC ideal for outdoor installations where exposure to sunlight and potential physical impact are concerns.

When using ABS for outdoor applications, UV-stabilized formulations must be specified to prevent degradation and discoloration over time. Even with stabilization, ABS may not perform as well as PC in extreme outdoor conditions.

Nylon offers good mechanical properties for outdoor applications but requires special consideration for its moisture absorption characteristics. In humid environments, nylon may absorb moisture, which can affect dimensional stability and electrical insulation properties. Glass-reinforced nylons can improve stability but at a higher cost.

For indoor MCB electrical enclosure applications, where environmental challenges are less severe, ABS often represents the optimal balance of performance and cost-effectiveness. Its good impact resistance, adequate heat resistance for indoor environments, and lower cost make it suitable for residential and commercial electrical panels.

In applications where superior impact resistance is required, such as in schools, hospitals, or industrial facilities where equipment might be subject to impact, polycarbonate provides enhanced protection. The transparency of PC can also be beneficial for visual inspection of components without opening the enclosure.

Nylon finds its niche in specialized indoor applications where higher temperature resistance or exceptional mechanical strength is required, such as near equipment that generates significant heat or in manufacturing environments where chemical exposure is a concern.

Electrical enclosures must meet specific safety standards and certifications to ensure they provide adequate protection in their intended applications. Understanding these requirements is essential for proper material selection.

The most relevant standards for circuit breaker enclosure boxes include:

UL Certification: In the United States, Underwriters Laboratories (UL) sets safety standards for electrical enclosures. UL listing indicates that a product has been tested and meets specific safety requirements. The parallel Canadian standard is cUL .

CE/UKCA Marking: In Europe and the United Kingdom, electrical enclosures must comply with relevant EU directives and UK regulations respectively. The CE or UKCA mark indicates conformity with health, safety, and environmental protection standards .

BS EN 61439-3: This British and European standard specifically applies to distribution box enclosures and consumer unit enclosures for residential, commercial, and industrial applications. It specifies requirements for design verification, temperature rise, mechanical operation, and other critical safety factors .

Compliance with these standards typically requires that materials meet specific performance criteria for:

Flame retardancy: Materials must resist ignition and limit flame spread to prevent fire propagation.

Thermal stability: Enclosures must maintain structural integrity and protective properties at elevated temperatures.

Impact resistance: Materials must withstand physical impacts appropriate to the application environment.

Environmental resistance: Enclosures must protect against ingress of solid objects and liquids, typically specified by IP (Ingress Protection) ratings .

ABS can meet necessary standards for many applications, particularly when flame-retardant formulations are used. Its balance of properties makes it suitable for a wide range of indoor applications where extreme conditions are not expected .

Polycarbonate typically exceeds requirements for impact resistance and UV stability, making it ideal for applications where superior environmental resistance is needed. Flame-retardant PC formulations are widely available and recognized by certification bodies .

Nylon offers exceptional thermal performance that can facilitate compliance with temperature rise requirements, particularly in applications with high ambient temperatures or significant internal heat generation. Glass-reinforced nylons can provide enhanced dimensional stability for precision applications .

While initial cost is often a primary consideration in material selection, taking a comprehensive view of return on investment (ROI) and lifecycle costs provides a more accurate assessment of the economic implications of enclosure material choices.

ABS enclosures typically have the lowest initial cost, making them attractive for budget-conscious projects. However, their shorter service life in demanding environments may lead to higher replacement costs over time

Polycarbonate enclosures command a price premium of 30-50% over ABS but typically offer significantly longer service life, particularly in outdoor applications. The reduced replacement frequency and lower maintenance requirements often justify the higher initial investment

Nylon enclosures are the most expensive option initially but provide exceptional durability in high-temperature and chemically aggressive environments. Their superior mechanical properties can make them the most cost-effective choice in specific demanding applications where other materials would fail prematurely

The maintenance requirements vary significantly between materials:

ABS may require more frequent replacement in outdoor applications due to UV degradation, potentially increasing long-term costs

Polycarbonate maintains its properties longer in outdoor environments, reducing replacement frequency and associated labor costs

Nylon offers excellent durability but may require more careful installation to address moisture absorption concerns in humid environments

Beyond direct maintenance and replacement costs, the potential cost of enclosure failure should factor into the economic analysis:

Equipment damage from water ingress or environmental exposure can far exceed the cost of the enclosure itself.

System downtime resulting from enclosure failure can have significant economic impacts, particularly in commercial and industrial settings.

Safety implications of enclosure failure represent both ethical and potential liability concerns that must be considered in the economic analysis

When these factors are considered, the material with the lowest initial cost may not provide the best overall value. A thorough lifecycle cost analysis that considers all these factors is essential for making economically optimal material selection decisions.

Laiwo offers a comprehensive range of certified circuit breaker enclosure boxes designed to meet the diverse needs of residential, commercial, and industrial applications:

ABS Enclosures: Our ABS MCB electrical enclosures provide cost-effective protection for indoor applications, with flame-retardant formulations that meet relevant safety standards. These enclosures are ideal for residential consumer units and commercial distribution panels where budget constraints are a consideration.

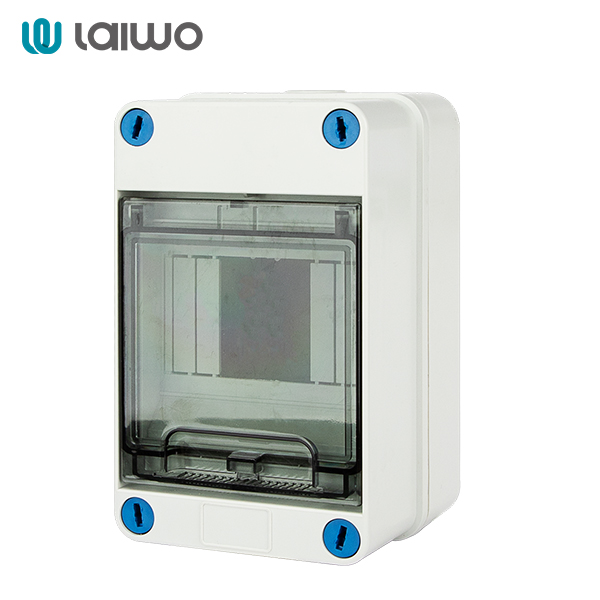

Polycarbonate Enclosures: For outdoor consumer unit enclosure applications, our polycarbonate offerings provide exceptional UV resistance, impact strength, and long-term weatherability. These enclosures are available with IP65 and higher ratings for reliable outdoor protection.

Nylon Enclosures: Our nylon breaker enclosure products are engineered for the most demanding applications, with high temperature resistance and exceptional mechanical strength. These are particularly suited for industrial environments where chemical resistance or elevated temperatures are concerns.

All Laiwo enclosures are manufactured to exacting quality standards and carry relevant certifications for their target markets, including CE/UKCA marking and compliance with BS EN 61439-3 where applicable. Our technical team can provide guidance on material selection and installation best practices to optimize performance and value.

Learn More:

Plastic Distribution Box Enclosures: Boosting Your Residential Project

INQUIRY NOW