Next: Metal Vs. Plastic Distribution Boxes: Choosing The Right One For Your Project

IP Rating Essentials: The article decodes the IP (Ingress Protection) code, explaining what each digit signifies—ranging from protection against solid objects to varying levels of water ingress—clarifying how to interpret and apply these ratings for outdoor circuit breaker enclosures.

Material Comparison: Metal vs. Plastic: It contrasts metal and plastic enclosure materials—highlighting metal’s advantages in strength, fire resistance, grounding, and durability, versus plastic’s benefits in corrosion resistance, lighter weight, and ease of installation.

Product Types & Application Scenarios: The blog explores different enclosure types suitable for varied applications (e.g., residential, commercial, industrial), stressing the importance of choosing designs aligned with circuit type, environmental exposure, and operational requirements.

Environmental Considerations: It emphasizes the need to select enclosures with appropriate IP ratings—such as IP65 or higher—for protection against dust, rain, UV, and other outdoor elements, tailored to the installation environment.

Safety Certifications & Compliance: The article underscores the importance of ensuring enclosures comply with relevant standards and certifications (e.g., IP codes, CE, UKCA), which guarantee safety, reliability, and regulatory compliance.

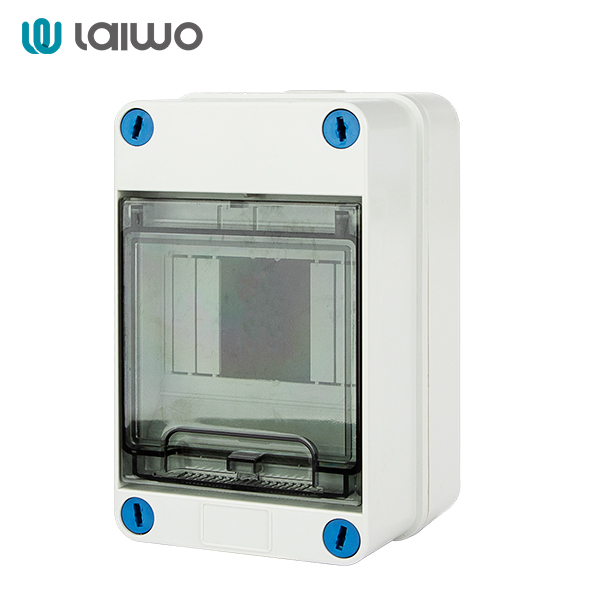

Laiwo’s Solutions: Finally, the blog introduces Laiwo’s range of outdoor enclosure solutions—highlighting their compliance with safety standards, customization options, and suitability across diverse environments.

Material Considerations: Metal vs. Plastic Enclosures

Product Types and Applications

Installation Environment Analysis

| First Digit | rotection Level (Description) | Second Digit | Protection Level (Description) |

| 0 (or X) | Not rated / No protection | 0 (or X) | Not rated / No protection |

| 1 | Protected against solid objects ≥50mm (e.g., accidental hand contact) | 1 | Protection against vertically falling droplets (e.g., condensation) |

| 2 | Protected against solid objects ≥12.5mm (e.g., accidental finger contact) | 2 | Protection against vertically dripping water (enclosure tilted up to 15°) |

| 3 | Protected against solid objects ≥2.5mm (e.g., tools and wires) | 3 | Protection against water spray (up to 60° off vertical) |

| 4 | Protected against solid objects ≥1mm (e.g., tools, wires, small objects) | 4 | Protection against splashing water (from any direction) |

| 5 | Dust protected (limited ingress permitted without harmful effects) | 5 | Protection against low-pressure water jets (from any angle) |

| 6 | Dust-tight (no ingress of dust) | 6 | Protection against powerful water jets (from any direction) |

| 7 | Watertight against temporary immersion (up to 1m for 30 min) | ||

| 8 | Watertight against continuous immersion (under pressure, beyond 1m) | ||

| 9 (or 9K) | Protection against high-pressure, high-temperature jets (e.g., washdowns) |

The International Protection (IP) rating system provides a standardized method for classifying the degree of protection provided by electrical enclosures against environmental intrusion. For outdoor applications, understanding IP ratings becomes crucial for selecting appropriate protection levels that match specific environmental conditions and regulatory requirements.

Learn More: Why IP Ratings Matter for Consumer Units?

| Material Type | Advantages | Considerations | Best Applications |

|---|---|---|---|

| Plastic | Corrosion resistant, lightweight, cost-effective, excellent insulation | Temperature limitations, UV degradation potential, lower impact resistance | Coastal areas, chemical environments, residential installations |

| Metal | High strength, excellent EMI shielding, heat dissipation, security | Corrosion potential, higher weight, galvanic compatibility | Industrial facilities, high-security areas, high-power applications |

The choice between metal and plastic enclosure materials significantly impacts performance, longevity, and cost-effectiveness in outdoor applications. Each material category offers distinct advantages and limitations that must be evaluated against specific application requirements and environmental conditions.'

Plastic enclosures provide excellent electrical insulation properties, reducing the risk of electrical faults and improving overall system safety. UV-stabilized formulations resist degradation from solar exposure, maintaining structural integrity and appearance throughout extended outdoor service. Additionally, plastic enclosures typically offer superior resistance to thermal cycling, reducing stress-related failures in temperature-variable environments.

The lightweight nature of plastic enclosures simplifies installation procedures, reduces structural support requirements, and minimizes shipping costs. For distribution box enclosure applications requiring frequent access or repositioning, plastic materials offer practical advantages that translate into reduced labor costs and improved installation flexibility.

Metal enclosures, typically constructed from stainless steel, aluminum, or coated carbon steel, provide superior mechanical protection and security for high-value installations. The inherent strength of metal construction offers excellent resistance to impact damage, vandalism, and unauthorized access attempts.

Heat dissipation characteristics of metal enclosures provide advantages in high-power applications where thermal management becomes critical. Metal construction facilitates the use of additional cooling mechanisms and provides better electromagnetic interference (EMI) shielding for sensitive electronic components.

However, metal enclosures require careful consideration of galvanic corrosion, environmental compatibility, and protective coating maintenance. In corrosive environments, the long-term cost of ownership may favor plastic alternatives despite higher initial metal enclosure costs.

Learn More: Metal Vs. Plastic Distribution Boxes: Choosing The Right One For Your Project

The selection of appropriate enclosure types depends on the specific electrical protection devices they house and the operational requirements of the installation. Understanding the characteristics and requirements of different product categories enables informed decision-making and optimal system design.

Miniature Circuit Breaker (MCB) enclosures form the foundation of most electrical distribution systems, providing overcurrent protection for individual circuits. The mcb electrical enclosure must accommodate not only the breaker itself but also provide adequate space for wiring connections, labeling, and future expansion requirements.

Modern mcb enclosure designs incorporate features such as transparent covers for visual inspection, multiple entry points for cable routing, and modular construction for system scalability. The selection of appropriate MCB enclosures requires consideration of current ratings, breaking capacity, and environmental conditions to ensure reliable long-term operation.

Residual Current Device (RCD) enclosures provide critical electrical safety protection by detecting current imbalances that indicate potential electrocution hazards. The rcd enclosure must provide reliable environmental protection while maintaining accessibility for regular testing and maintenance procedures.

RCD enclosures often require additional space for test buttons and indicator lights, with clear marking requirements for safety compliance. The selection of rcd enclosure plastic or metal construction depends on environmental conditions, security requirements, and maintenance access considerations.

Residual Current Circuit Breaker with Overcurrent protection (RCBO) devices combine MCB and RCD functionality in a single unit, requiring specialized rcbo enclosure designs that accommodate the increased complexity and connection requirements. RCBO enclosures must provide adequate space for both overcurrent and residual current protection mechanisms while maintaining compact installation footprints.

Learn More:

MCBs Guide: Types, Functions & Electrical Safety Tips

Understanding the difference between MCB RCCB and RCBO

Consumer unit enclosure systems provide centralized electrical distribution for residential and small commercial applications. These comprehensive solutions typically incorporate multiple protection devices, main switching capability, and extensive connection facilities within weatherproof outdoor-rated enclosures.

The design of consumer unit enclosures must balance accessibility requirements with environmental protection, providing clear organization of circuits while maintaining IP-rated performance throughout the service life.

Learn More: Distribution Boards: A Comprehensive Guide for Professionals and Consumers

The selection of appropriate breaker enclosure solutions requires thorough analysis of installation environments, operational requirements, and long-term service conditions. Different environments present unique challenges that directly impact enclosure selection criteria and performance expectations.

Residential outdoor electrical installations typically prioritize cost-effectiveness, aesthetic integration, and ease of maintenance. Circuit breaker enclosure box selection for residential applications often favors plastic construction for corrosion resistance and cost control, with IP65 ratings providing adequate protection for most climate conditions.

Residential installations benefit from enclosures with clear labeling capabilities, intuitive access mechanisms, and compatibility with standard residential electrical components. The integration of outdoor consumer unit enclosure solutions with home automation systems increasingly influences selection criteria for modern residential projects.

Commercial outdoor electrical systems require enhanced reliability, expanded capacity, and improved accessibility for maintenance operations. Commercial breaker enclosure selection typically emphasizes modular design, expansion capability, and compatibility with building management systems.

The higher electrical loads and more complex distribution requirements of commercial installations often necessitate larger enclosures with enhanced heat dissipation capabilities. Security considerations may favor metal construction or specialized locking mechanisms to prevent unauthorized access.

Industrial environments present the most demanding conditions for outdoor electrical enclosures, with exposure to chemicals, mechanical damage, extreme temperatures, and high electrical loads. Industrial circuit breaker enclosure selection requires careful analysis of specific environmental hazards and operational requirements.

Industrial applications often require specialized materials, enhanced IP ratings, and additional features such as explosion-proof construction, corrosion-resistant coatings, or electromagnetic shielding. The selection process must consider not only immediate installation requirements but also long-term maintenance access and system expansion needs.

Compliance with relevant safety standards and certifications represents a non-negotiable requirement for professional outdoor electrical installations. Understanding applicable standards and certification requirements ensures regulatory compliance, professional liability protection, and optimal safety performance.

The IEC 61439 series provides international standards for low-voltage switchgear and controlgear assemblies, establishing requirements for design verification, routine testing, and performance validation. Compliance with IEC standards ensures international compatibility and facilitates global project deployment.

Professional electrical contractors must ensure that selected enclosures carry appropriate certifications for their specific regional requirements, including UL listing for North American applications, CE marking for European installations, or other relevant regional certifications.

Our engineering team works closely with electrical professionals to develop customized solutions that optimize performance, compliance, and cost-effectiveness for specific application requirements. With extensive experience in international markets, Laiwo enclosures meet global certification requirements while providing superior long-term reliability.

Key advantages of Laiwo enclosure solutions include:

Comprehensive IP65+ ratings with verified performance testing

Advanced material formulations optimized for outdoor environments

Modular design systems supporting easy expansion and modification

Complete certification compliance for global market requirements

Technical support throughout the project lifecycle

Whether your project requires standard distribution box enclosure solutions or specialized custom designs, Laiwo's technical expertise and comprehensive product range provide the foundation for successful outdoor electrical installations. Contact our technical team to discuss your specific requirements and discover how Laiwo solutions can optimize your next outdoor electrical project.

INQUIRY NOW