Next: Why RCBOs Are a Must-Have in Modern Distribution Boards

Electrical safety is a critical aspect of any modern infrastructure—whether residential, commercial, or industrial. Protection devices such as Residual Current Devices (RCDs) and Residual Current Circuit Breakers with Overcurrent Protection (RCBOs) are widely used to mitigate the risk of electric shock, fire and equipment failure. For engineers, consultants, and procurement decision-makers in the B2B arena, understanding the functional differences between an RCD and an RCBO is essential for specifying the right equipment, ensuring compliance with IEC standards, and optimizing the reliability of distribution systems.

An RCD primarily detects earth leakage current. Its core purpose is to disconnect the circuit if there is a difference between live and neutral currents, which usually indicates current leakage to earth—a potentially fatal fault. They do not provide protection against overload or short circuits.

An RCBO combines the residual current detection function of an RCD with the overcurrent and short-circuit protection of an MCB (Miniature Circuit Breaker). In one device, an RCBO ensures both leakage protection (typically 30mA or 100mA trip threshold) and overcurrent protection based on its rated current curve (e.g., B or C curve).

Learn More:

Understanding the difference between MCB RCCB and RCBO

RCBO 6A–40A: B2B Use for Residential & Industrial Circuit Protection

| Protection Type | RCD | RCBO |

|---|---|---|

| Earth leakage | ✔ | ✔ |

| Overload and short-circuit | ✖ | ✔ |

| Individual circuit isolation | Requires MCB combination | Integrated |

Interpretation:

For systems that require only leakage protection (e.g., general sockets or group protection), an RCD paired with MCBs can suffice. However, for targeted, high-reliability protection on individual circuits—especially where infrastructure downtime is unacceptable—a dedicated RCBO is the more robust solution.

Both devices must meet IEC/EN 61008 (for RCDs) and IEC/EN 61009 (for RCBOs). Modern revisions of IEC 60364 for wiring regulations emphasize selective and localized protection to minimize nuisance tripping across multiple circuits.

Residential: Evolving regulations (e.g. 18th Edition in the UK) recommend or mandate RCBOs for individual final circuits to prevent whole-house shutdown when one circuit trips.

Industrial and OEM Panels: RCBOs preserve continuity by eliminating unnecessary knock-outs of multiple loads. They are increasingly required in OEM designs for specialized loads like HVAC, automation, and EV charging.

RCD + MCB configurations can cause multiple circuits to trip when only a single branch is faulty. This results in unnecessary downtime and troubleshooting challenges in production or hospitality environments.

Limits fault to a single outgoing circuit

Minimizes downtime and maintenance hours

Easier troubleshooting for facility management

Eliminates the need for large RCD main switches covering multiple circuits

RCBOs come in multiple rated currents (6A, 10A, 16A, 20A, 32A, 40A, etc.) and trip curves (B, C). This allows precise matching of load characteristics to protection demand. For instance:

Lighting circuits → 6A or 10A RCBO, type B curve

Sockets → 16A or 20A, type C curve

Motor or HVAC loads → 32A or higher, type C

RCDs, meanwhile, cover larger groups of circuits at higher current ratings (e.g., 63A, 80A, 100A) with purely leakage sensing.

While RCBOs typically cost more per unit than RCDs+MCBs, they reduce panel complexity, save space, simplify wiring, and reduce operational downtime — all of which translate into cost savings over the lifecycle of the system.

Integrating RCBOs into consumer units allows differentiation through higher safety grade and compliance. Additionally, fewer components reduce assembly time and inventory complexity.

EV charging points are high-demand, continuous-use loads. They produce not only AC residual current but also potential DC fault residuals. Specifying modern Type A or Type B RCBOs in EV consumer units prevents fire hazards, meets EV-specific standards, and ensures that only the affected charging circuit trips—keeping other circuits (lighting, security) operational.

Learn More: Why RCBOs Are a Must-Have in Modern Distribution Boards

Required protection type (leakage only vs leakage + overload)

Circuit criticality and downtime tolerance

Individual circuit ratings and earth leakage sensitivity

Wiring Regulations in target market

If multiple circuits are protected collectively and low selectivity is acceptable → RCD with MCBs

If selective disconnection, individual circuit integrity and modern compliance is needed → RCBO

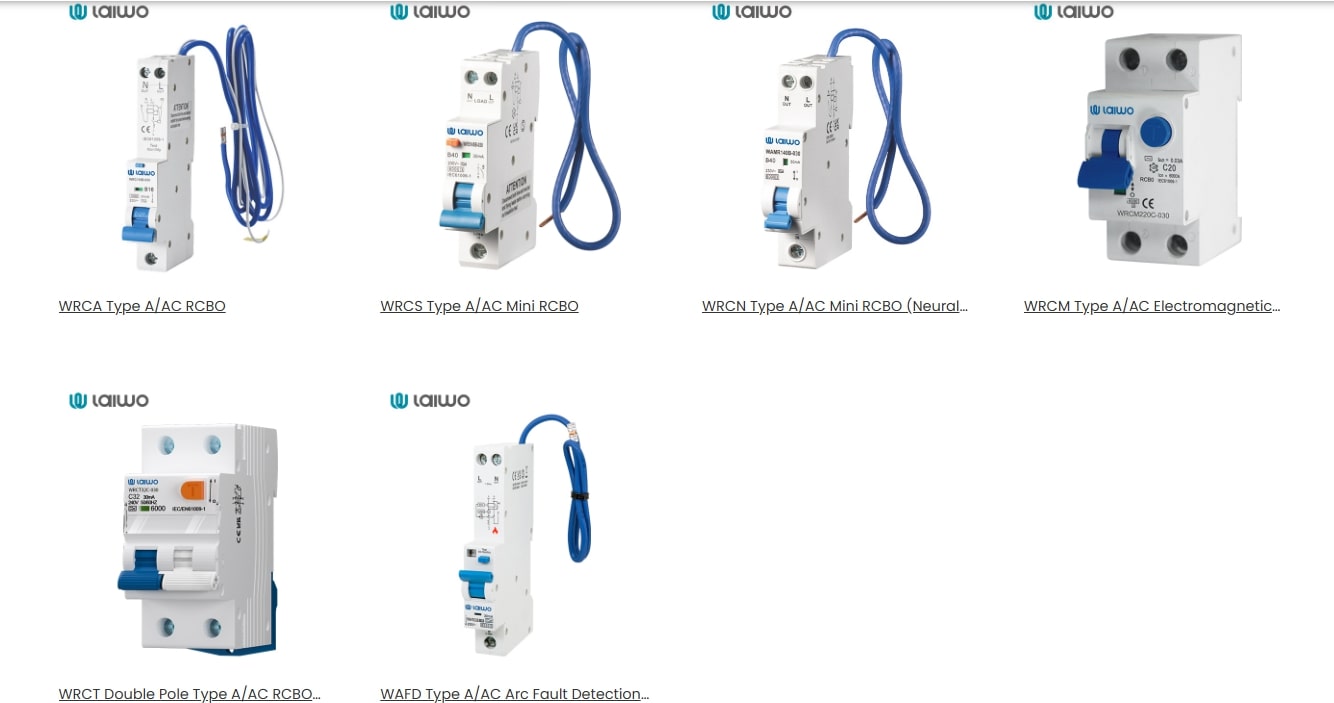

We offer a full portfolio of Type A and Type AC RCBOs rated from 6A to 40A, with 30mA or 100mA residual current thresholds. All units are tested in accordance with EN61009-1, with certifications including CB, SEMKO, UKCA.

Advantages of our RCBOs:

High breaking capacity (6kA)

Type A for EV and electronics-sensitive loads

Compact one-module width

4000 mechanical endurance cycles

Neutral pole switching for full isolation

In modern electrical design, reliance on traditional RCD+MCB combinations may still apply for small, non-critical groups of circuits. However, as compliance frameworks evolve and system complexity increases, RCBOs are becoming the de facto choice for individual circuit safety and continuity of supply.

For engineers and B2B buyers, the operational, technical, and commercial benefits of RCBO integration are clear: higher system resilience, easier maintenance, and improved regulatory alignment — particularly in residential consumer units, industrial control boards, and EV charging applications.

If you have any questions or require expert assistance with your electrical needs, our dedicated customer service team is ready to help. Give us a call or send us an email today and our dedicated team will provide you with the answers and support you need.

INQUIRY NOW